Difference between revisions of "Lulzbot AO-101 3D Printer"

| (32 intermediate revisions by 3 users not shown) | |||

| Line 10: | Line 10: | ||

|status = available | |status = available | ||

|availability = training | |availability = training | ||

| − | |talk_to = Claudio, Ben, | + | |talk_to = Claudio, Ben, Danny or Cliff |

|purchase_date = 05/24/2013 | |purchase_date = 05/24/2013 | ||

|disposal_date = | |disposal_date = | ||

| Line 24: | Line 24: | ||

== Location == | == Location == | ||

| − | The LulzBot AO-101 3D Printer is currently on it's dedicated work station in the common room next to the vinyl cutter. | + | The LulzBot AO-101 3D Printer is currently on it's dedicated work station in the common room next to the vinyl cutter. Or at least will be after 5/24/2013. |

== Features == | == Features == | ||

| Line 42: | Line 42: | ||

===Allowed Filament Vendors=== | ===Allowed Filament Vendors=== | ||

| − | * | + | * [https://www.lulzbot.com/?q=catalog/plastic-filament LulzBot] |

| − | * | + | * [https://ultimachine.com/catalog/print-materials UltiMachine] |

| − | * | + | * [http://shop.seemecnc.com/Filament-Plastics_c8.htm SeeMeCNC] |

== Recommended Safety Equipment == | == Recommended Safety Equipment == | ||

| Line 67: | Line 67: | ||

=== Replace === | === Replace === | ||

| − | + | Please leave a donation for any printer use. Filament costs on average $50 a kg (2.2lb) with shipping. Please leave a dollar or two for each hour the print takes. You can donate by giving cash to a board member, with paypal or with purchasing filament. [http://www.midsouthmakers.org/donations/ Make a donation now.] Please purchase reels for ease of use and stability. Coiled filament will work but can be a pain. | |

==Specs== | ==Specs== | ||

| Line 80: | Line 80: | ||

|Pulleys | |Pulleys | ||

|Extrusions | |Extrusions | ||

| + | |Heated Bed | ||

| + | |Glass Bed | ||

|- | |- | ||

|RAMBo v1 | |RAMBo v1 | ||

| Line 89: | Line 91: | ||

|GT2 16 tooth | |GT2 16 tooth | ||

|Misumi 2020 | |Misumi 2020 | ||

| + | |Prusa PCB Heater MK1 | ||

| + | |Borosilicate with PET film | ||

|- | |- | ||

| + | |} | ||

===Calibration Standard=== | ===Calibration Standard=== | ||

| − | '' | + | ''DO NOT CHANGE/MODIFY/ALTER without checking with Claudio/Orias first.'' |

{| class="wikitable" | {| class="wikitable" | ||

|- | |- | ||

| Line 124: | Line 129: | ||

|8 | |8 | ||

|135 | |135 | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | ===Budaschnozzle specs=== | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | | Thermistor | ||

| + | | Heater resistor | ||

| + | | Connectors | ||

| + | |- | ||

| + | | 100k Honeywell Thermistor | ||

| + | | 6.8 Ohm | ||

| + | | | ||

|- | |- | ||

|} | |} | ||

=Slic3r Configurations= | =Slic3r Configurations= | ||

| − | Known good working Slic3r configurations will be stored on | + | Known good working Slic3r configurations will be stored on [https://github.com/MidsouthMakers/slic3r-configs MidsouthMakers GitHub] |

==Usage== | ==Usage== | ||

*Navigate to where ever you would like to sync the contents to | *Navigate to where ever you would like to sync the contents to | ||

| − | * In a terminal window issue the following command: | + | * In a terminal window issue the following command: |

| + | '''git clone https://github.com/MidsouthMakers/slic3r-configs.git''' | ||

| + | * Once synced, run Slic3r and load the desired configuration. | ||

| + | |||

| + | =Usage= | ||

| + | The following services are hosted at [http://192.168.1.10:8080 192.168.1.10] or [http://printer3d.local printer3d.local] | ||

| + | ==Repetier-Server== | ||

| + | [http://192.168.1.10:3344/#/printer/A101/control http://192.168.1.10:3344/#/printer/A101/control]Status: Recommended | ||

| + | |||

| + | ==OctoPrint== | ||

| + | [http://printer3d.local:5000/ http://printer3d.local:5000/]Status: Octoprint no longer in use, use Repetier-server above | ||

| + | |||

| + | |||

| + | [http://printer3d.local:8080/?action=stream? OctoPrint webcam stream]Status: Not working | ||

| + | |||

| + | =Authorized Users= | ||

| + | Ben | ||

| + | Cliff | ||

| + | Dan | ||

| + | Joe | ||

| + | Reese | ||

| + | Dru | ||

| + | Claudio | ||

| + | Mark | ||

| + | Andrew | ||

| + | Dan | ||

| + | |||

| + | ==Maintenance Performed== | ||

| + | *6/20/2013 Replaced small herringbone gear on extruder stepper motor. Lost one gear tooth after ~13lb of filament. | ||

| + | *6/21/2013 Replaced PET print surface. | ||

| + | *10/24/2013 Haksaw replaced wiring harness and connectors for the hotend. | ||

Latest revision as of 01:23, 20 May 2017

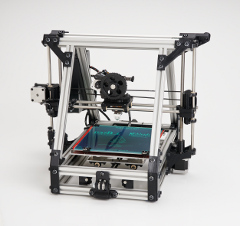

| Lulzbot AO-101 3D Printer | |

|---|---|

3D Printer | |

| Information | |

| Owner | Midsouth Makers |

| Tool Category | Tool -> CNC Tool |

| Model | LulzBot AO-101 |

| Serial | VERALE47120240 |

| Purchased On | 2013-05-24 |

| Cost | $0 ($1725) |

| Status | Available |

| Availability | Training required to use |

| Labels | |

| Media | |

| QRCode | |

| This tool is to be only used by authorized users. If you wish to learn how to use this tool please contact one of the authorized individuals. |

| Questions? Talk to Claudio, Ben, Danny or Cliff for help or more information. |

Location

The LulzBot AO-101 3D Printer is currently on it's dedicated work station in the common room next to the vinyl cutter. Or at least will be after 5/24/2013.

Features

- Usable Print Area: 200mm x 190mm x 100mm (7.9in x 7.5in x 3.9in)

- Top Print Speed: 150mm/sec

- Print Tolerance: 0.2mm (0.008in) in X and Y axes. Z axis is dependent on layer thickness

- Layer Thickness: 0.075mm (0.0029in) to 0.4mm

- Stock filament size: 3mm

Consumables

- ABS 3mm plastic filament

- PLA 3mm plastic filament

- Nylon 3mm plastic filament

- Laywoo-D3 plastic filament

- PET print surface on a borosilicate glass bed

- ABS & acetone solution (for ABS first layer adhesion)

Allowed Filament Vendors

Recommended Safety Equipment

- COMMON SENSE

- Beware of Pinch Points.

- The heated bed gets hot.

- The nozzle gets hot too.

Prior to each use

Verify

- X and Y belts are taut

- Filament loaded properly

- Print surface prepped: (PET with ABS solution for ABS printing/Bare glass for PLA/Garolite or cellulose based material for Nylon)

- Home all axes prior to using the manual movement controls

After each use

Clean

- Clean bed of any left over filament.

- If using personal filament reload the space filament and prime the nozzle by bringing it to temp and verifying extrusion.

- Home all axes

- Power off the printer using the power switch on the left hand side of the printer (for now)

Replace

Please leave a donation for any printer use. Filament costs on average $50 a kg (2.2lb) with shipping. Please leave a dollar or two for each hour the print takes. You can donate by giving cash to a board member, with paypal or with purchasing filament. Make a donation now. Please purchase reels for ease of use and stability. Coiled filament will work but can be a pain.

Specs

| Board | Firmware | Hot end | Installed nozzle diameter | Motors | Belts | Pulleys | Extrusions | Heated Bed | Glass Bed |

| RAMBo v1 | Marlin 1.0 | Budaschnozzle 1.2 | 0.5mm | NEMA 17 | GT2 | GT2 16 tooth | Misumi 2020 | Prusa PCB Heater MK1 | Borosilicate with PET film |

Calibration Standard

DO NOT CHANGE/MODIFY/ALTER without checking with Claudio/Orias first.

| Motor | Steps | Max Length | Microstep Mode | Digipot |

| X | 50.25 | 190 | 8 | 135 |

| Y | 50.25 | 200 | 8 | 135 |

| Z | 756.00 | 100 | 8 | 170 |

| E0 (Extruder 1) | 408 | NA | 8 | 135 |

Budaschnozzle specs

| Thermistor | Heater resistor | Connectors |

| 100k Honeywell Thermistor | 6.8 Ohm |

Slic3r Configurations

Known good working Slic3r configurations will be stored on MidsouthMakers GitHub

Usage

- Navigate to where ever you would like to sync the contents to

- In a terminal window issue the following command:

git clone https://github.com/MidsouthMakers/slic3r-configs.git

- Once synced, run Slic3r and load the desired configuration.

Usage

The following services are hosted at 192.168.1.10 or printer3d.local

Repetier-Server

http://192.168.1.10:3344/#/printer/A101/controlStatus: Recommended

OctoPrint

http://printer3d.local:5000/Status: Octoprint no longer in use, use Repetier-server above

OctoPrint webcam streamStatus: Not working

Authorized Users

Ben Cliff Dan Joe Reese Dru Claudio Mark Andrew Dan

Maintenance Performed

- 6/20/2013 Replaced small herringbone gear on extruder stepper motor. Lost one gear tooth after ~13lb of filament.

- 6/21/2013 Replaced PET print surface.

- 10/24/2013 Haksaw replaced wiring harness and connectors for the hotend.